DMAIC is a structured, data-driven problem-solving method used in Lean Six Sigma to improve existing processes. The acronym stands for Define, Measure, Analyze, Improve, and Control. DMAIC provides a clear roadmap for identifying root causes, reducing variation, and creating reliable, repeatable results across any industry, from manufacturing and logistics to healthcare, government, and service operations.

If you’re learning DMAIC as part of your path toward Six Sigma certification, this framework shows how structured problem-solving is applied in real-world improvement projects.

It remains the most widely used improvement framework in Lean Six Sigma because it gives teams a simple, repeatable approach for eliminating waste and achieving measurable outcomes.

The DMAIC process provides a step-by-step method for solving problems and improving quality.

DMAIC Explained

DMAIC is a five-phase improvement cycle used to enhance existing processes. Here’s a quick overview:

Define: Clarify the problem, project goals, and customer requirements

Measure: Quantify the current performance

Analyze: Identify root causes of defects and variation

Improve: Implement and test solutions

Control: Sustain the results and prevent regression

DMAIC stands for Define, Measure, Analyze, Improve, and Control.

How DMAIC Is Used in Six Sigma Certification Programs

DMAIC is the core problem-solving framework taught across Lean Six Sigma certification levels. Professionals are first introduced to DMAIC concepts during Six Sigma Yellow Belt certification, where the focus is on understanding the framework and supporting improvement projects.

As practitioners advance to Six Sigma Green Belt certification, DMAIC becomes the primary method used to lead data-driven improvement projects.

At the Six Sigma Black Belt certification level, professionals apply DMAIC to complex, cross-functional initiatives and mentor Green Belts in advanced analysis and problem-solving.

The Five DMAIC Phases (Step-by-Step Breakdown)

The DMAIC framework consists of five structured phases: Define, Measure, Analyze, Improve, and Control. Each phase plays a critical role in solving problems and driving process improvements.

| Phase | Purpose |

|---|---|

| Define | Identify the problem and set project goals based on customer needs. |

| Measure | Collect data to establish current process performance baselines. |

| Analyze | Identify root causes of inefficiencies or defects through data analysis. |

| Improve | Implement targeted solutions to address verified root causes. |

| Control | Monitor the improved process and sustain gains over time. |

Let’s take a closer look at each of the five DMAIC phases, starting with Define.

Define Phase

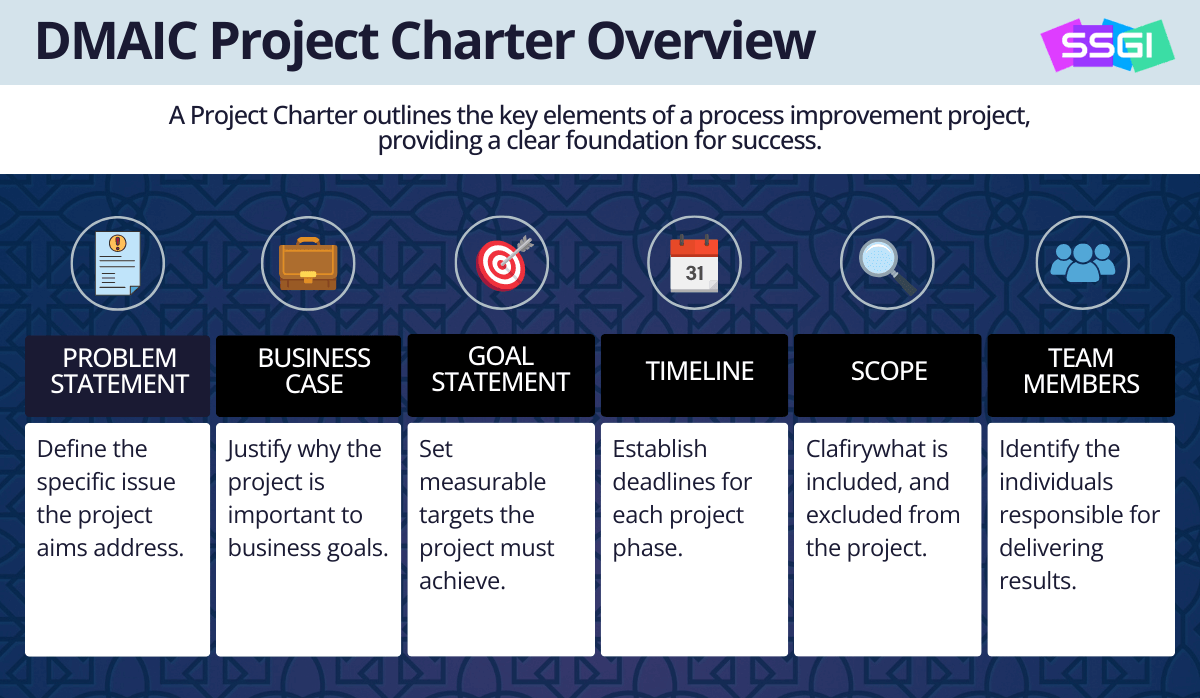

The Define phase establishes what problem you’re solving and why it matters. Teams clarify project goals, customer requirements, and the overall scope.

Activities typically include:

Creating the project charter

Writing problem and goal statements

Defining project boundaries (scope)

Gathering Voice of the Customer (VOC) insights

Building a high-level process map (SIPOC)

Example:

A government department defines the problem as: “Permit processing takes 38 days on average.” The goal: reduce processing time to 15 days.

Measure Phase

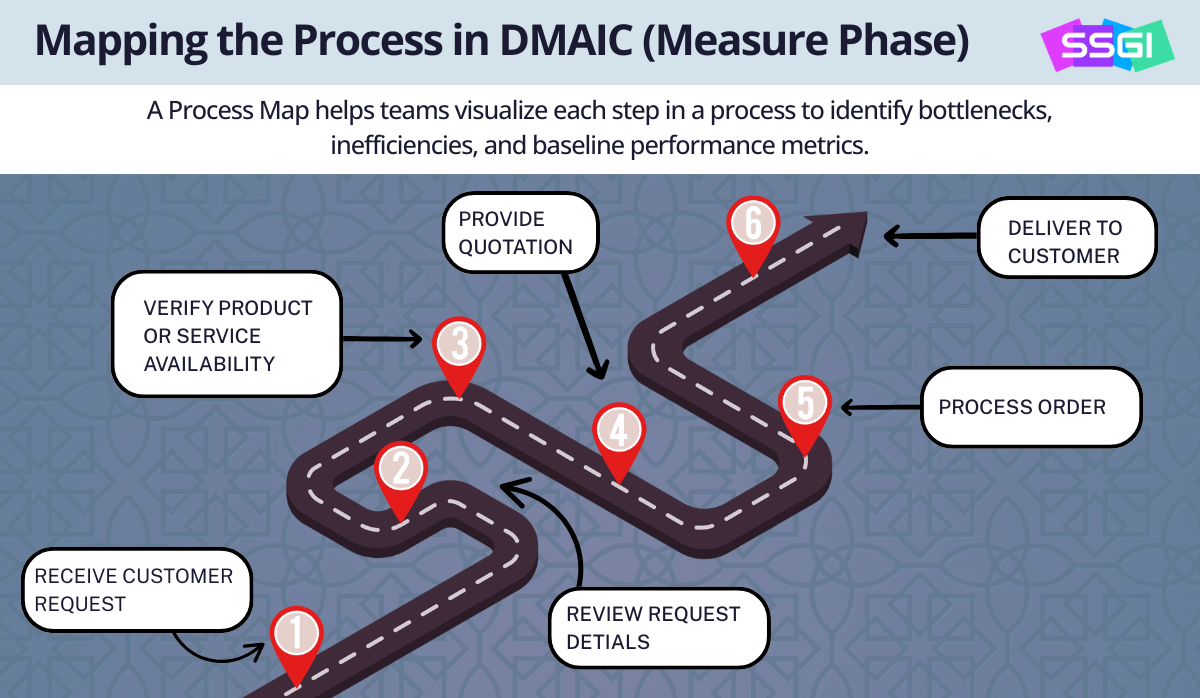

The Measure phase establishes a clear baseline so future improvements can be quantified. Teams gather reliable data to understand how the process is currently performing and to validate that the problem is measurable.

Activities typically include:

Identifying key performance metrics

Collecting accurate and relevant data

Validating measurement systems (MSA)

Mapping the current process in detail

Example:

A team measures average cycle time, number of handoffs, rework frequency, and defect rates to understand the true extent of variation before moving into analysis.

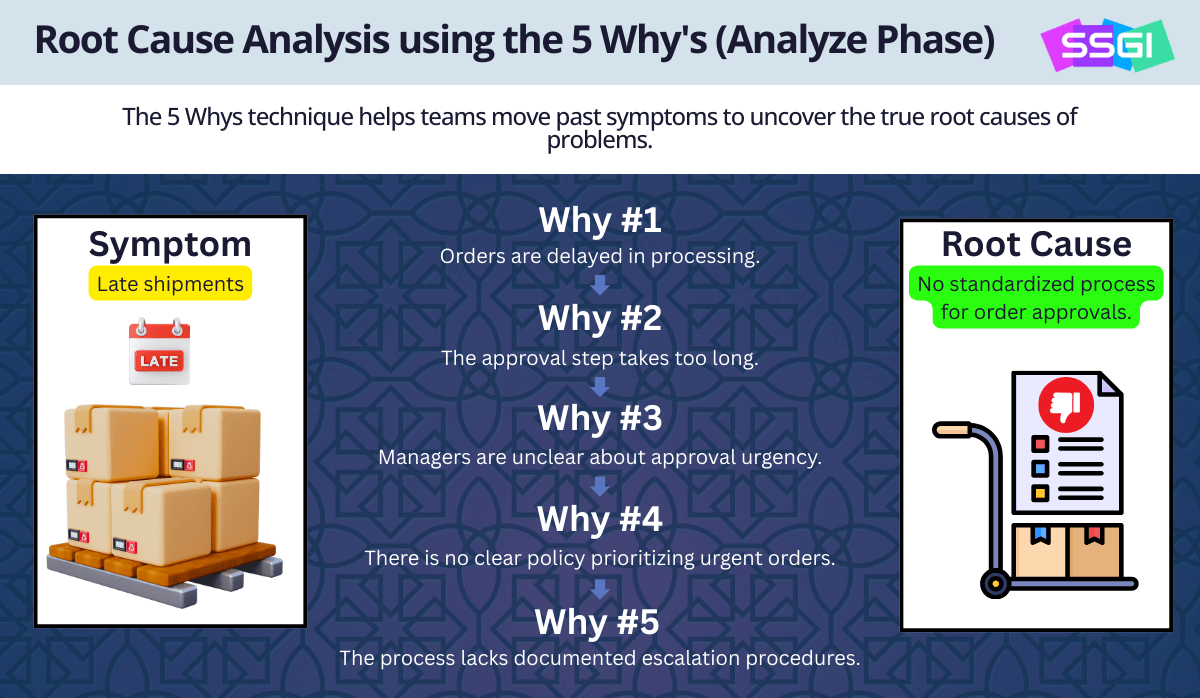

Analyze Phase

The Analyze phase is where teams identify and validate the true root causes of the problem. Instead of relying on assumptions, this phase uses data and structured analysis to determine what is actually driving poor performance.

Common tools and activities include:

Detailed process analysis

Cause-and-effect (fishbone) diagrams

5 Whys investigations

Hypothesis testing

Regression or correlation analysis

Outcome:

A verified list of root causes that directly contribute to the performance gap, ensuring the Improve phase targets the right issues.

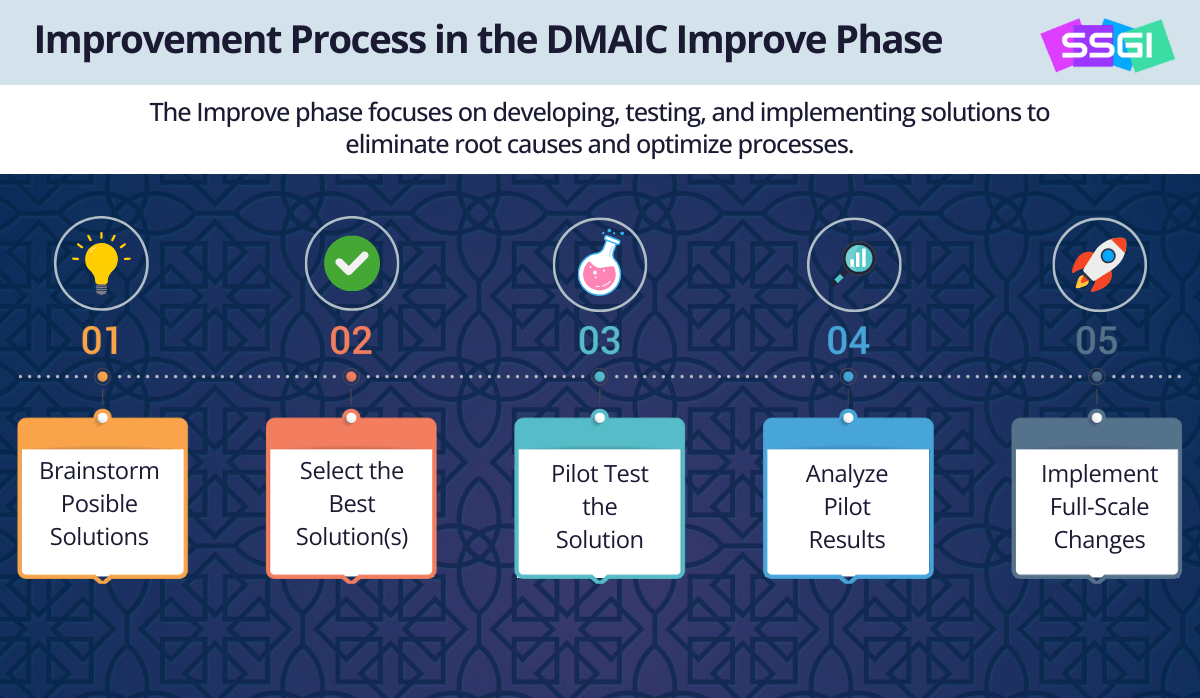

Improve Phase

The Improve phase focuses on developing, testing, and implementing solutions that address the verified root causes. Teams evaluate potential improvements, run controlled experiments, and select the most effective and sustainable options.

Activities typically include:

Brainstorming and evaluating improvement ideas

Conducting pilots or controlled experiments

Selecting and refining the best solution

Performing risk assessments

Planning and executing implementation

Example:

Teams may redesign forms, streamline steps, automate manual actions, clarify roles, or standardize tasks to eliminate variation and improve performance.

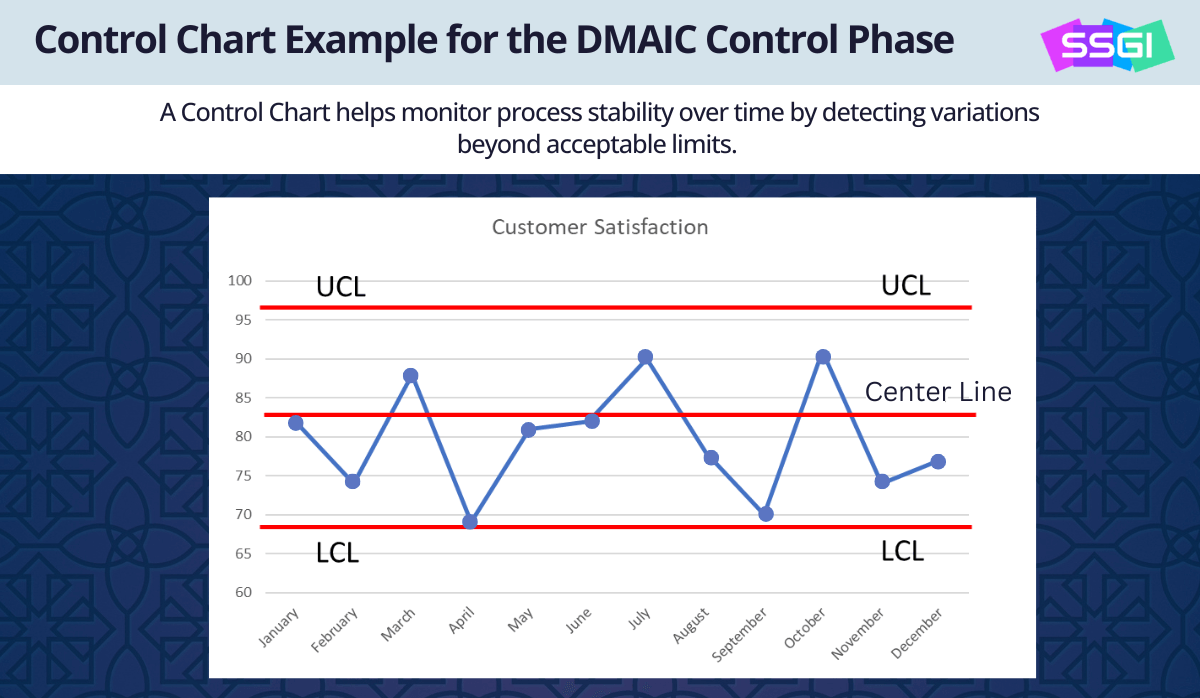

Control Phase

The Control phase ensures that improvements are sustained over the long term. Teams establish monitoring, documentation, and standardized procedures to prevent the process from reverting to its previous state.

Activities typically include:

Creating or updating standard operating procedures (SOPs)

Developing monitoring dashboards or scorecards

Using control charts to track ongoing performance

Providing training and documentation for stakeholders

Formalizing project handover to process owners

Purpose:

To maintain the gains achieved in the Improve phase and prevent the process from slipping back months later.

DMAIC Examples (Real Use Cases)

These brief real-world examples show how organizations use DMAIC to improve processes, reduce variation, and eliminate waste.

Healthcare Example

A hospital reduced emergency room wait times from 42 minutes to 18 minutes by mapping the triage workflow, identifying bottlenecks in manual charting, and implementing an electronic intake process.

Manufacturing Example

A plant cut defect rates by 60% after discovering calibration variation during the Analyze phase and implementing a new preventive maintenance schedule in the Improve phase.

Government Example

A city reduced permit approval times from 38 days to 14 days by eliminating redundant review steps and standardizing workflow handoffs across departments.

Customer Service Example

A support center shortened ticket resolution time by 40% by analyzing the highest-volume categories and redesigning the escalation process for complex requests.

How DMAIC Is Applied in Different Industries

The five DMAIC phases stay the same — but how they look in practice varies by industry. Here is a side-by-side view of how Healthcare and Manufacturing teams apply each step.

| DMAIC Phase | Healthcare Example | Manufacturing Example |

|---|---|---|

| Define | Reduce patient wait times in the ER | Lower defects in an assembly process |

| Measure | Collect data from check-in through triage | Track defect rates per 1,000 units |

| Analyze | Identify delays caused by manual charting | Pinpoint machine variation causing failures |

| Improve | Implement electronic health records (EHR) | Add new maintenance intervals |

| Control | Monitor patient throughput monthly | Use control charts to track defects |

DMAIC is universal — but its flexibility across industries is what makes it so effective.

Example Mini Case Study: Improving Order Fulfillment Time

A distribution center used DMAIC to reduce order fulfillment time from 3.5 days to 1.9 days. During the Analyze phase, the team discovered excessive queueing between picking and packing. They piloted a new batching method in the Improve phase, which eliminated 27% of total wait time. Control charts and SOP updates ensured the results remained stable over the next 12 months.

When to Use DMAIC (and When NOT To)

DMAIC is best used when you want to improve an existing process using data, structure, and root cause analysis. It is not the right approach for every situation.

Use DMAIC when:

You want to improve an existing process

There is measurable performance variation

The root cause of the problem is unknown

The solution is not obvious

You need measurable, data-driven results

Cross-functional alignment or standardization is required

Do NOT use DMAIC when:

You are designing a brand-new process or product → use DMADV

The solution is already known (“Just execute the fix”)

The issue is a one-time incident rather than a systemic problem

The goal is innovation, not optimization

You cannot rely on consistent or available data

In short: DMAIC improves processes that already exist. DMADV creates processes that need to be built from scratch.

DMAIC vs DMADV

DMAIC and DMADV are both Lean Six Sigma methodologies, but they serve very different purposes. DMAIC improves an existing process, while DMADV is used to design a new one from the ground up.

| Framework | When It’s Used | Purpose |

|---|---|---|

| DMAIC | Improving an existing process | Reduce variation, defects, and waste |

| DMADV | Designing a new process or product | Build quality into the design from the start |

In simple terms: DMAIC fixes something that already exists. DMADV creates something new. Organizations use DMAIC when the root cause is unclear and data analysis is needed, while DMADV is ideal when a process or product must be built to meet new customer or performance requirements.

DMAIC vs PDCA

DMAIC and PDCA are both continuous improvement methods, but they serve different purposes.

DMAIC is more rigorous, data-driven, and used when the root cause is unknown.

PDCA is lighter, faster, and used for quick improvements or daily process management.

Use DMAIC when:

— The problem is complex or recurring

— The root cause is unclear

— Data analysis is needed to validate solutions

Use PDCA when:

— You need rapid, iterative improvements

— The process is stable and well understood

— Teams want a simple cycle for daily problem solving

Benefits of DMAIC

DMAIC offers a structured, data-driven approach for improving existing processes, making it one of the most effective and widely used methodologies in Lean Six Sigma. By following each phase systematically, organizations can solve complex problems, reduce variation, and achieve measurable, long-lasting results.

Here are the key benefits of using DMAIC:

Reduces defects and variation

DMAIC helps teams identify the root causes of performance issues and eliminate the factors that lead to defects, errors, and inconsistency.

Improves customer satisfaction

By addressing problems that impact quality and service, DMAIC leads to faster, more reliable outcomes that directly improve the customer experience.

Reduces cost and waste

Through better resource utilization, fewer errors, and streamlined workflows, DMAIC lowers operational costs and eliminates non-value-added activities.

Streamlines workflows

Mapping and analyzing processes reveals bottlenecks, delays, and unnecessary steps, allowing organizations to create smoother, more efficient workflows.

Increases efficiency and speed

Teams are able to deliver products or services more quickly by reducing rework, standardizing procedures, and improving task sequencing.

Provides a repeatable, data-driven problem-solving approach

DMAIC promotes evidence-based decision-making and gives teams a consistent framework they can apply across departments and industries.

DMAIC’s disciplined structure not only solves today’s problems but helps organizations build a culture of continuous improvement and operational excellence.

DMAIC Tools (Common Tools Used in Each Phase)

Each phase of DMAIC uses specific tools to analyze problems, uncover root causes, validate solutions, and sustain improvements. These are the most widely used tools in Lean Six Sigma projects.

Pareto Charts

Used to identify the most significant contributors to defects or inefficiencies, helping teams prioritize improvement efforts.

Fishbone Diagrams (Cause-and-Effect)

Helps teams visualize potential root causes during the Analyze phase by categorizing contributing factors.

Process Mapping

Creates a detailed view of how work flows through the system to identify redundancies, delays, and waste.

Value Stream Mapping

A Lean tool that shows value-added versus non–value-added activities across a process, used to eliminate waste.

Control Charts

Used in the Control phase to track performance over time and detect abnormal variation.

Failure Mode and Effects Analysis (FMEA)

A proactive tool for identifying potential failure points in a process and addressing them before defects occur.

Why DMAIC Is Important

DMAIC is important because it provides a structured, data-driven approach for improving existing processes. Instead of relying on assumptions, teams use measurable evidence to identify root causes, test solutions, and sustain gains over time.

- ✓ Reduces defects and variation to improve product and service quality.

- ✓ Eliminates waste and increases workflow efficiency.

- ✓ Improves customer satisfaction through faster, more reliable outcomes.

- ✓ Supports data-driven decision making instead of guesswork.

- ✓ Creates a repeatable improvement framework that can be used across any industry.

DMAIC is the foundation of Lean Six Sigma, and many advanced methodologies build on its structure to achieve long-term operational excellence.

According to ASQ , DMAIC is a structured problem-solving approach used for improving existing processes and ensuring sustainable results.

Frequently Asked Questions About DMAIC

What is DMAIC?

DMAIC is a structured, five-phase process improvement methodology used in Six Sigma to identify problems, eliminate root causes, and achieve lasting results. It stands for Define, Measure, Analyze, Improve, and Control.

What are the five phases of DMAIC?

The five phases of DMAIC are Define, Measure, Analyze, Improve, and Control.

Is DMAIC the same as Six Sigma?

No, DMAIC is the core process improvement framework used within Six Sigma. Six Sigma is the broader methodology focused on reducing defects, while DMAIC provides the step-by-step approach to improve existing processes.

Is DMAIC the same as Kaizen?

No, DMAIC and Kaizen are different. DMAIC is a structured, five-phase problem-solving process used in Six Sigma, while Kaizen is a philosophy focused on continuous, incremental improvements over time.

What is the difference between DMAIC and PDCA?

DMAIC is data-driven and more statistical, while PDCA is simpler and more iterative.

What industries use DMAIC?

Healthcare, manufacturing, finance, education, technology, IT, government, and more.

Is DMAIC only used in Six Sigma?

While DMAIC originated with Six Sigma, it is now used broadly across all continuous improvement efforts.

How long does a typical DMAIC project take?

Depending on scope, DMAIC projects can range from a few weeks to several months.

What is the main purpose of DMAIC?

DMAIC provides a structured, data-driven approach to problem-solving and process improvement. Its primary purpose is to identify the root causes of inefficiencies, implement targeted solutions, and sustain long-term improvements across business processes.

Can DMAIC be used outside of manufacturing?

Yes. Although DMAIC originated in manufacturing, it is now widely applied across industries such as healthcare, finance, education, technology, and government. Any organization looking to reduce defects, streamline operations, or improve service quality can benefit from DMAIC.

What tools are most commonly used during DMAIC projects?

Key tools include Fishbone Diagrams, Process Mapping, Control Charts, Pareto Charts, Value Stream Mapping, and Failure Mode and Effects Analysis (FMEA). These tools help teams analyze processes, identify root causes, implement improvements, and maintain process control.

What is the DMAIC Approach used for?

Improving existing processes, reducing variation, and solving root-cause problems.

What are examples fo DMAIC projects?

Cycle time reduction, defect reduction, waste elimination, workflow redesign, and service speed improvements.

Who should use DMAIC?

Professionals in quality, operations, healthcare, government, logistics, tech, customer service, and continuous improvement.

DMAIC vs DMADV: Which should I choose?

Use DMAIC for improving existing processes. Use DMADV when designing something new.

#1 in Process Improvement Training | McGraw Hill Award Winning Instructor | Baldrige Foundation & Project Management Institute Partner