SIX SIGMA CERTIFICATION IN Manufacturing: Benefits, Jobs & Career Impact

In manufacturing, small inefficiencies can lead to big losses. Six Sigma gives manufacturers the tools to identify waste, reduce variation, and build quality into every step of the production process.

At SSGI, our online Six Sigma Certification programs, developed by McGraw-Hill award-winning professor Dr. Barry Shore, help professionals and organizations in the manufacturing sector streamline operations, increase output consistency, and improve profitability.

How Six Sigma Transforms Manufacturing Operations

Across the manufacturing sector, organizations use Lean Six Sigma to enhance efficiency, reduce waste, and deliver consistent product quality. By combining data-driven analysis with continuous improvement principles, companies can identify hidden inefficiencies, strengthen production flow, and achieve measurable performance gains.

From automotive suppliers to electronics and packaging firms, Six Sigma empowers manufacturers to cut costs, boost throughput, and elevate quality standards—all while building a culture of operational excellence that sustains long-term success.

Why Choose SSGI for Manufacturing Certification

Industry-Trusted, Expert-Led Training

At SSGI, we specialize in professional certifications designed for real-world application. Our programs are trusted by over 1,000 leading corporations—including Tesla, Walmart, Disney, and GE—and are used to train teams at every level of the manufacturing process.

Best Value for Industry-Leading Training

SSGI provides all-inclusive pricing with no surprise fees for exams, retakes, or certification renewals. Plus, our training is developed by Dr. Barry Shore, a McGraw-Hill award-winning professor.

Accredited by PMI, SHRM, and CPD

SSGI certifications meet the highest industry standards, ensuring global recognition for professionals in government and corporate sectors. Also earn professional credits like PDUs and CEUs.

Trusted by Manufacturing companies & The Fortune 500

Our clients include Tesla, Amazon, General Electric, Caterpillar, and Siemens, along with numerous manufacturing organizations worldwide. SSGI’s Lean Six Sigma certifications are trusted and recognized across the global manufacturing industry for developing leaders in quality and operational excellence.

Certifications That Never Expire

Once certified with SSGI, your credential lasts for life—no renewal fees, no expiration, and no hidden costs.

100,000+ Certified Professionals & $500M in Cost Savings

SSGI graduates have successfully led cost-cutting, process optimization, and efficiency-improving initiatives, generating over $500M in savings for organizations worldwide.

Dr. Barry Shore | Expert Instructor

Dr. Barry Shore, a globally recognized expert in operations management, brings over 40 years of experience to Lean Six Sigma training. As a McGraw-Hill award-winning author and professor emeritus, his groundbreaking work has empowered professionals from Fortune 500 companies, government agencies, and leading organizations worldwide.

Industry Recognized Accreditations | Baldrige Foundation Partner | #1 in Process Improvement for Manufacturing Companies

![]()

SSGI is trusted by leading manufacturing companies around the world.

Top Reasons Why You Should Get Six Sigma Certification in Manufacturing

Increase Career & Salary Potential

In the manufacturing sector, Six Sigma certification is one of the most valuable career credentials. Professionals with Black Belt certification earn $95K+ on average and are trusted to lead quality, efficiency, and process improvement initiatives.

Improve Quality

Manufacturers rely on precision and efficiency to deliver consistent, high-quality products. Six Sigma methodologies help eliminate defects, streamline production workflows, and ensure quality is built into every process step. Lean Manufacturing initiatives, powered by Lean Six Sigma, have helped organizations reduce waste, lower costs, and achieve operational excellence across the manufacturing value chain.

Cut Cost & Reduce Waste

In manufacturing, inefficiencies directly affect quality, lead time, and profitability. Six Sigma’s structured approach to process improvement reduces variation, eliminates waste, and ensures every resource contributes to maximum output efficiency.

Strengthen Leadership & Culture

Manufacturers that implement Six Sigma foster a data-driven, problem-solving culture among employees. This methodology empowers teams to identify root causes, make evidence-based decisions, and drive continuous improvement across production lines and operations—resulting in stronger quality, higher efficiency, and long-term competitiveness.

Improve Customer Satisfaction

Manufacturers produce millions of products every year, making process efficiency essential for quality and customer trust. Six Sigma strengthens production systems by reducing variation, improving cycle times, and ensuring consistent, high-quality output—leading to greater reliability and satisfaction among customers and stakeholders.

Six Sigma Certification in Manufacturing: Job Opportunities & Salary Insights

Six Sigma-certified professionals are in high demand across the manufacturing sector, where quality, efficiency, and cost reduction are top priorities. Manufacturers seek experts in quality management, process engineering, production leadership, and continuous improvement.

With Six Sigma certification, professionals gain data-driven skills to reduce variation and optimize production systems, valuable across industries like automotive, electronics, food, and industrial manufacturing.

As an official Baldrige Foundation partner, the organization behind the Malcolm Baldrige National Quality Award, SSGI aligns its certifications with the highest standards of process excellence. Our programs are trusted by leading manufacturers including Tesla, GE, 3M, and Caterpillar, as well as thousands of small and mid-sized companies worldwide.

Who Hires Six Sigma-Certified Professionals in Manufacturing?

Manufacturers across multiple sectors actively recruit Six Sigma-certified professionals to lead quality improvement and process optimization initiatives.

✔ Automotive Manufacturers:

Defect reduction, production efficiency, and supplier quality management.

✔ Electronics & Technology Producers:

Process consistency, precision manufacturing, and yield optimization.

✔ Industrial & Heavy Equipment Companies:

Operational excellence, maintenance reliability, and throughput improvement.

✔ Food & Beverage Manufacturers:

Waste reduction, process standardization, and quality control in production and packaging.

Overview of Six Sigma Certification in Manufacturing

Modern manufacturing operates in highly competitive environments that demand precision, efficiency, and data-driven problem-solving. Six Sigma certification equips professionals at all levels with the skills to reduce variation, eliminate waste, and enhance product quality, core principles for achieving operational excellence in manufacturing.

At SSGI, we offer a full range of Lean Six Sigma certification programs that help manufacturers strengthen production systems, improve throughput, and develop a culture of continuous improvement.

Our courses are designed to provide practical, industry-relevant training that aligns with real-world manufacturing challenges, from optimizing assembly lines to improving supplier performance and quality control.

Recommended Programs

Choose the Right Certification for Your Manufacturing Career

Many professionals in the manufacturing industry pursue all three Belt levels to gain a complete understanding of Six Sigma methodologies.

Six Sigma certification in manufacturing follows a tiered approach, similar to martial arts rankings, ranging from foundational to advanced expertise. Each level is designed to help professionals progressively build skills and take on increasing leadership roles:

🟡 Yellow Belt – Ideal for beginners.

🟢 Green Belt – Designed for mid-level professionals.

⚫ Black Belt – For government leaders.

🏆 Master Black Belt – The highest level, for experts.

Yellow Belt Training & Certification for Manufacturing Professionals

Best for: Production associates, quality technicians, and team leaders involved in manufacturing process improvements.

Overview: The Yellow Belt certification provides foundational knowledge of Lean Six Sigma principles, enabling professionals to identify inefficiencies and support process optimization efforts on the production floor.

✅ Gain introductory training in Lean Six Sigma methodology.

✅ Learn to identify and reduce waste in manufacturing processes.

✅ Support Green and Black Belts in quality and efficiency improvement projects.

Green Belt Training & Certification for Manufacturing Professionals

Best for: Production supervisors, process engineers, quality managers, and mid-level manufacturing professionals.

Overview: The Green Belt certification equips professionals to lead process improvement projects within manufacturing environments. Green Belts work alongside Black Belts to implement data-driven solutions that enhance product quality, reduce defects, and optimize production flow.

✅ Learn how to apply Six Sigma methodologies in manufacturing operations.

✅ Gain hands-on skills in project management and statistical process control.

✅ Reduce waste, improve throughput, and strengthen overall process efficiency.

Black Belt Training & Certification for Manufacturing Professionals

Best for: Senior engineers, plant managers, operations directors, and continuous improvement leaders.

Overview: Black Belt-certified professionals lead large-scale process improvement initiatives and manage cross-functional teams within manufacturing organizations. This certification is ideal for professionals aiming to drive operational excellence and achieve measurable production improvements.

✅ Master advanced data-driven problem-solving and leadership techniques.

✅ Lead complex process improvement projects across manufacturing operations.

✅ Implement strategies to reduce defects, optimize resources, and increase profitability.

Master Black Belt Training & Certification for Manufacturing Professionals

Best for: Senior executives, plant directors, operations leaders, and continuous improvement strategists.

Overview: The Master Black Belt certification is the highest level of Six Sigma expertise, empowering professionals to lead enterprise-wide process excellence initiatives across manufacturing operations. Master Black Belts serve as mentors, coaches, and strategic advisors, ensuring alignment between improvement projects and organizational goals.

✅ Coach and mentor Six Sigma teams across production facilities.

✅ Design and oversee large-scale quality and efficiency programs.

✅ Drive long-term performance gains and sustainable operational excellence.

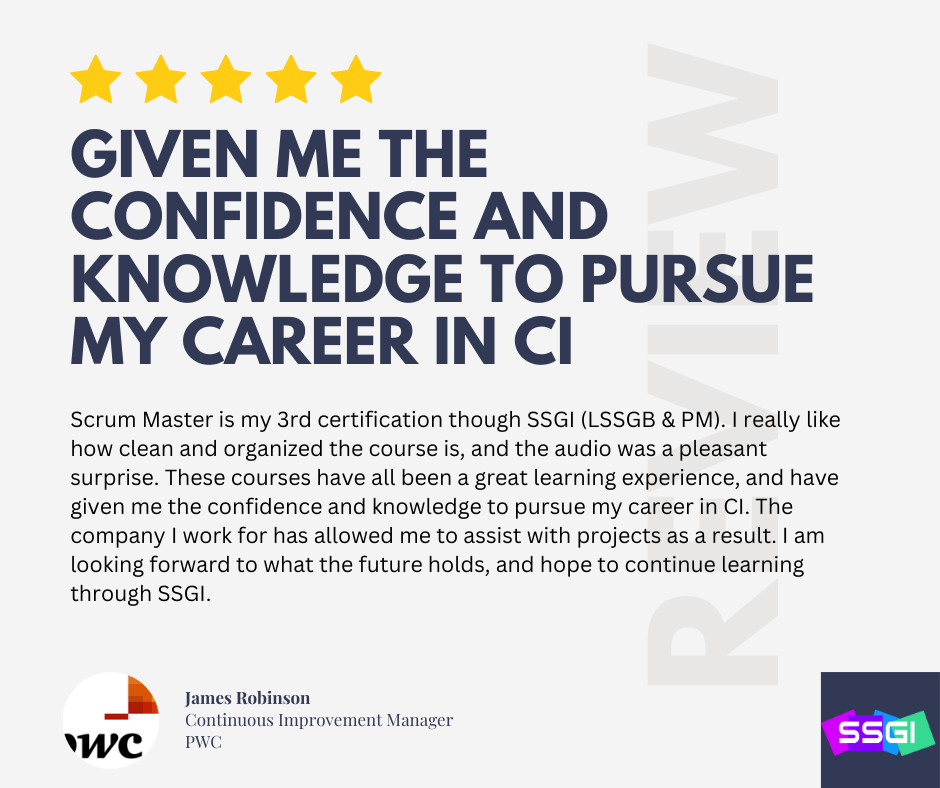

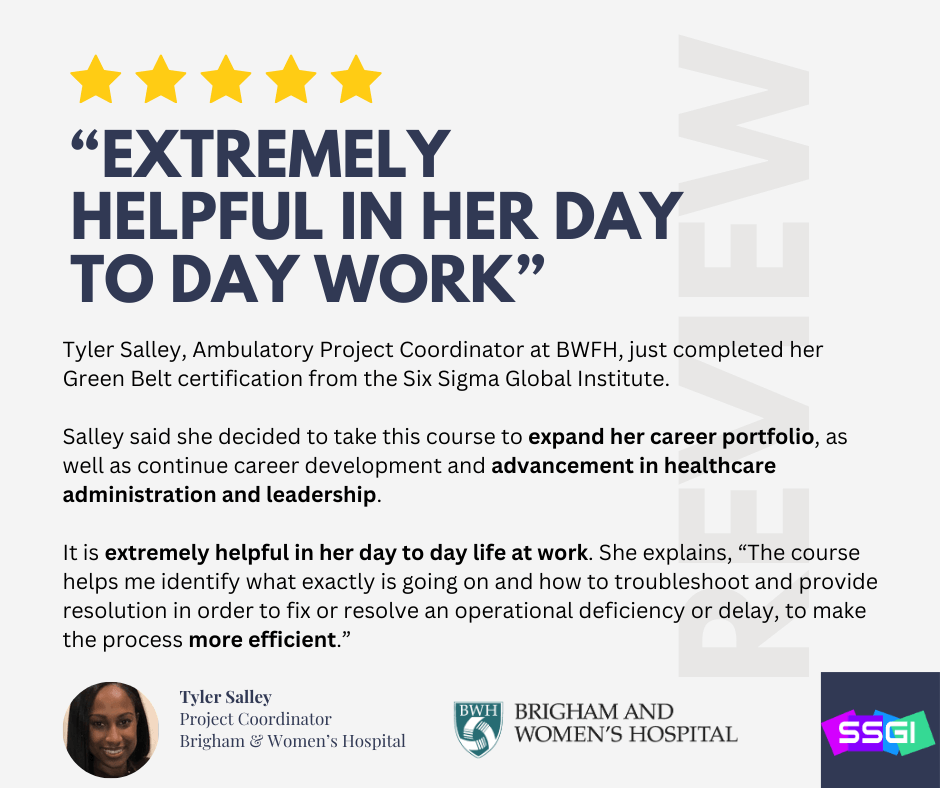

What Our Clients Say About SSGI

Lean Six Sigma in Manufacturing FAQs

What is Six Sigma in manufacturing?

Six Sigma in manufacturing is a data-driven approach that minimizes defects, reduces waste, and improves production quality through continuous process improvement techniques such as DMAIC (Define, Measure, Analyze, Improve, Control).

How does Six Sigma improve manufacturing processes?

By using statistical analysis and process mapping, Six Sigma helps identify root causes of variation, streamline operations, and create standardized workflows, leading to higher quality and lower production costs.

What are the benefits of Lean Six Sigma for manufacturers?

Lean Six Sigma helps manufacturers reduce waste, enhance product consistency, increase throughput, and improve customer satisfaction—all while lowering operational costs and strengthening competitiveness.

What are examples of Six Sigma projects in manufacturing?

Common Six Sigma projects include reducing assembly time, improving equipment reliability, lowering defect rates, optimizing supply chain logistics, and enhancing product inspection accuracy.

Who should get Six Sigma certified in manufacturing?

Professionals such as production engineers, quality managers, plant supervisors, and process improvement specialists benefit most from Six Sigma certification in manufacturing.

What’s the difference between Lean and Six Sigma in manufacturing?

Lean focuses on eliminating waste and improving process flow, while Six Sigma targets reducing variation and defects. Together, they create a balanced system of efficiency and precision in manufacturing.

Which Six Sigma certification is best for manufacturing professionals?

Green Belt and Black Belt certifications are most popular in manufacturing, as they provide the tools needed to lead improvement projects, analyze data, and optimize production performance.

How long does it take to complete Six Sigma training for manufacturing?

Most online programs can be completed in 2–6 weeks per belt level, depending on the individual’s pace and the depth of study.

What industries within manufacturing use Six Sigma?

Six Sigma is used across automotive, aerospace, electronics, industrial machinery, food & beverage, and pharmaceutical manufacturing to improve quality and reduce waste.

Is Six Sigma certification worth it for manufacturing professionals?

Yes. Certified professionals often see significant career growth, leadership opportunities, and salary increases, as manufacturers prioritize employees skilled in quality and efficiency improvement.

How much do Six Sigma-certified manufacturing professionals earn?

According to industry data, Six Sigma Black Belts in manufacturing often earn between $95,000 and $120,000+ annually, depending on experience and role.

Can Six Sigma be combined with Lean manufacturing principles?

Absolutely. Many organizations adopt Lean Six Sigma to integrate Lean’s focus on waste reduction with Six Sigma’s data-driven approach to quality improvement.

What tools are commonly used in Six Sigma manufacturing projects?

Tools include Pareto charts, control charts, cause-and-effect diagrams, process mapping, FMEA (Failure Mode and Effects Analysis), and statistical process control (SPC).

How do Six Sigma and Industry 4.0 work together?

Six Sigma complements Industry 4.0 technologies like automation, IoT, and data analytics by providing structured methods to analyze performance data and improve digital manufacturing systems.

Do manufacturers prefer online or in-person Six Sigma training?

Most modern manufacturers prefer flexible, self-paced online training programs that allow employees to learn while working—without disrupting production schedules.