What is the difference between Lean Six Sigma and PMP?

The main difference between Lean Six Sigma and PMP is what they are designed to do: Lean Six Sigma focuses on improving business processes by reducing defects, variation, and waste, while PMP focuses on managing and delivering projects on time, within scope, and on budget.

Lean Six Sigma is most often used in operations, quality, and continuous improvement roles where the goal is to make how work gets done more efficient and reliable. PMP, on the other hand, is designed for professionals responsible for leading projects, coordinating stakeholders, managing risk, and delivering defined outcomes across a project life cycle.

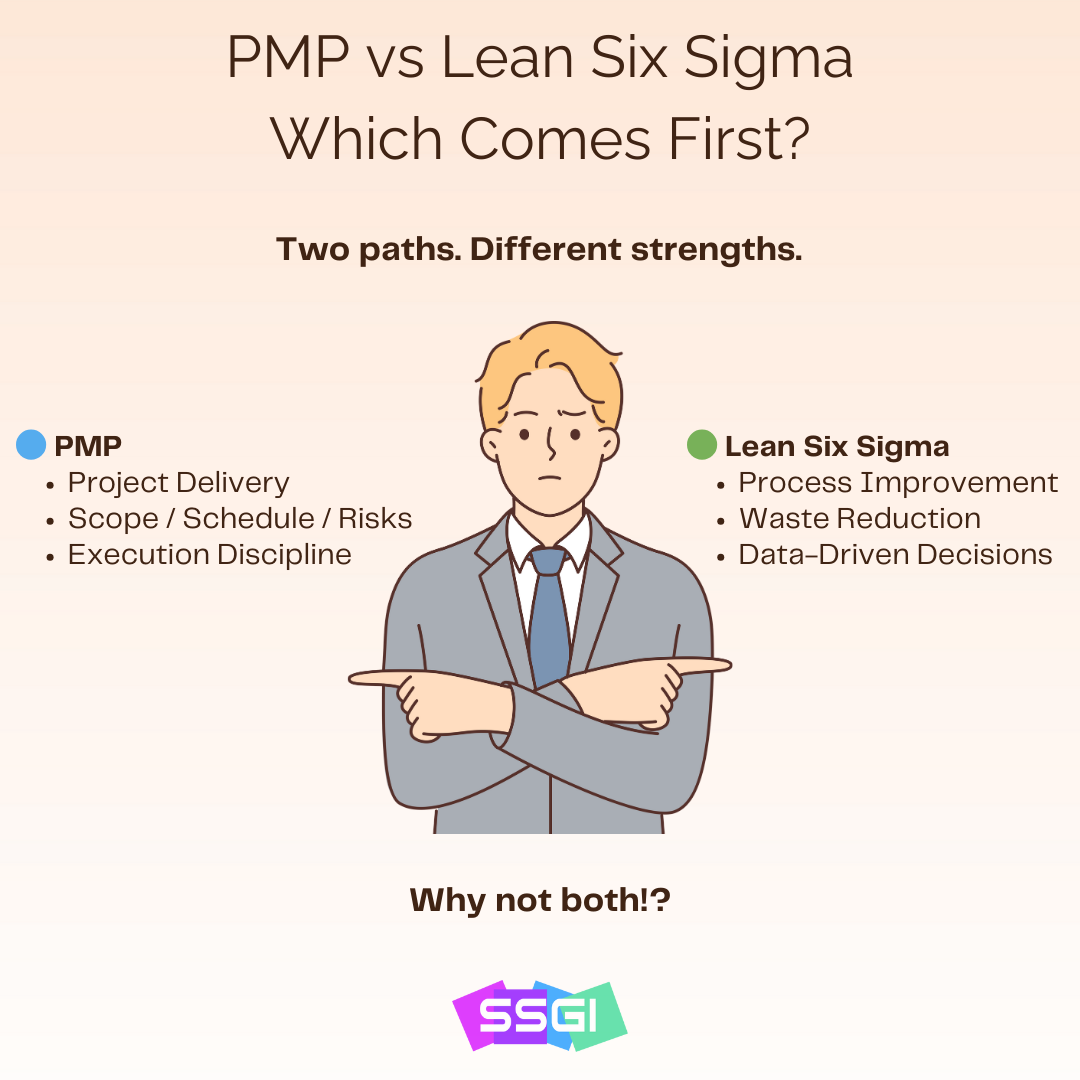

Both certifications are respected and frequently appear in job descriptions. The better choice depends on whether your role is primarily centered on improving ongoing processes or leading time-bound projects. In many careers, professionals eventually benefit from earning both.

This guide breaks down the key differences between Lean Six Sigma and PMP, explains how employers use each certification, and helps you decide which one makes the most sense to pursue first.

Key Differences Between Lean Six Sigma and PMP

The primary differences between Lean Six Sigma and PMP are focus, methodology, application, and certification structure.

Focus: PMP focuses on managing and delivering projects, while Lean Six Sigma focuses on improving and stabilizing business processes.

Methodology: PMP follows the PMBOK framework and project life-cycle phases, while Lean Six Sigma uses DMAIC and Lean principles to reduce defects and waste.

Application: PMP applies to any type of project with a defined start and end, while Lean Six Sigma is primarily used to improve ongoing operations and workflows.

Certification Structure: PMP is a single, standardized certification, while Lean Six Sigma includes multiple levels (Yellow Belt, Green Belt, Black Belt, Master Black Belt).

Leadership Emphasis: PMP emphasizes stakeholder management, leadership, and team coordination, while Lean Six Sigma emphasizes analytical problem-solving and process control.

Risk Management: PMP manages risk across the full project life cycle, while Lean Six Sigma addresses risk through process control and performance monitoring.

Lean Six Sigma vs PMP at a Glance (Quick Comparison)

This section breaks down the key differences between Six Sigma and PMP so you can quickly understand how the two compare.

Lean Six Sigma and PMP serve different purposes in an organization.

Lean Six Sigma: A data-driven methodology focused on improving process performance, reducing defects, variation, and waste in ongoing operations.

PMP: A project management framework focused on planning, executing, and delivering projects on time, within scope, and within budget.

Primary focus

- Lean Six Sigma: Process improvement, efficiency, and quality

- PMP: Project delivery, scope, schedule, cost, and stakeholders

Typical roles

Lean Six Sigma: Operations managers, quality professionals, continuous improvement leaders

PMP: Project managers, program managers, implementation leads

Where it is used

Lean Six Sigma: Manufacturing, services, healthcare, finance, government, operations

PMP: IT, construction, consulting, engineering, enterprise initiatives

Core frameworks

Lean Six Sigma: DMAIC, Lean principles, statistical analysis

PMP: PMBOK, project life-cycle phases, knowledge areas

What is Lean Six Sigma?

Lean Six Sigma is not a project management framework. It is a process improvement methodology.

Lean Six Sigma combines Lean (eliminating waste and improving flow) with Six Sigma (reducing defects and variation using data and statistics). Together, they form a structured way to improve performance and deliver more value with fewer resources.

Typical Lean Six Sigma work includes:

Mapping how work is done today and finding bottlenecks

Using data to understand where defects, delays, and variation come from

Removing non value added steps and rework

- Applying the DMAIC (Define, Measure, Analyze, Improve, Control) framework

Designing better processes that are simpler, faster, and more reliable

Measuring before and after results so improvements are clear

Lean Six Sigma practitioners often work inside operations, quality, supply chain, service delivery, healthcare, finance, and government. Their job is to make processes better and more stable so the business runs smoother.

Common Lean Six Sigma certification levels are Yellow Belt, Green Belt, Black Belt and Master Black Belt. Each level builds deeper capability in tools and project leadership.

What is PMP?

PMP (Project Management Professional) is a globally recognized project management certification from the Project Management Institute (PMI). It validates that you can lead and manage projects using a formal project management framework.

PMP focuses on:

Initiating, planning, executing, monitoring, and closing projects

Defining scope, schedule, and budget

Managing risk, issues, and changes

Coordinating teams and stakeholders

Ensuring projects deliver expected outcomes

PMP holders are commonly project managers, program managers, implementation leads, or senior professionals who are accountable for delivering cross functional initiatives.

To earn the PMP you need documented project experience plus formal training hours, then you must pass a comprehensive exam. Keeping the credential active requires ongoing professional development units (PDUs) every three years.

Key Differences Between Lean Six Sigma and PMP (Side-by-Side Comparison)

The table below expands on the key differences between Lean Six Sigma and PMP, including how each impacts cost, career outcomes, and long-term value.

| Category | Lean Six Sigma | PMP |

|---|---|---|

1. Focus Operations vs Projects | Lean Six Sigma improves how ongoing processes perform by applying proven Lean Six Sigma tools and methods — ideal for reducing defects, improving flow, and enhancing customer experience in day-to-day operations. | PMP focuses on planning and delivering one-time, time-bound initiatives such as system implementations, product launches, or strategic projects. |

2. Methodology & Tools | Uses structured methods like DMAIC (Define, Measure, Analyze, Improve, Control), waste reduction tools, capability analysis, and statistical root-cause techniques. | Uses formal project life-cycle stages and knowledge areas including scope, schedule, cost, risk, procurement, and stakeholder management. |

3. Cost & Renewal | Generally lower upfront cost. Most Lean Six Sigma certifications do not require renewal fees or ongoing maintenance. | PMP has a higher exam fee and requires renewal every 3 years by earning 60 PDUs and paying a renewal fee. |

4. Salary & Career Impact | Lean Six Sigma certification can increase earning potential by ~19%, especially in quality, operations, and continuous improvement roles. | PMP certification can increase salary by ~22% on average and is often required for senior project management roles. |

Lean Six Sigma or PMP first?

If you are trying to decide what to do first, it helps to look at the kind of problems you want to spend your time solving.

- ✔️ Are already working as a project manager or implementation lead.

- ✔️ Work in fields like IT, construction, engineering, consulting, product launches, or enterprise change programs.

- ✔️ Are accountable for schedules, budgets, and stakeholder alignment.

- ✔️ Need a credential that many organizations explicitly list in project manager job descriptions.

- ✔️ Work in operations, quality, manufacturing, logistics, customer service, healthcare, or shared services.

- ✔️ Want to be the person who can fix broken processes and eliminate recurring problems.

- ✔️ Enjoy data, root cause analysis, and structured problem solving.

- ✔️ Want quick wins that you can show with clear before-and-after metrics.

Who is Lean Six Sigma best for?

Lean Six Sigma tends to be the strongest fit for:

Operations managers and supervisors

Quality and CI professionals

Analysts and specialists in supply chain, logistics, finance, or service operations

Healthcare and public sector professionals working on efficiency and access

Early to mid career professionals who want a practical, project based way to stand out

Because Lean Six Sigma is used across industries, it is especially useful if you want flexibility to move between sectors while keeping a relevant skill set.

Who is PMP best for?

PMP tends to be the strongest fit for:

Full time project managers and program managers

Senior professionals who routinely lead cross functional initiatives

Consultants and implementation leads who manage client projects

IT, engineering, construction, and enterprise transformation roles

If your day to day work is mainly structured around projects with clear start and end dates, PMP strongly validates your expertise in leading that work.

Do you need to choose, or can you do both?

You do not have to lock yourself into only one discipline. In fact, many of the most effective leaders combine both:

Lean Six Sigma to understand processes, find root causes, and design better ways of working

PMP to plan and deliver the initiatives that implement those improvements at scale

Universities and professional programs increasingly encourage professionals to understand both so they know when to use each discipline and where they overlap.

Over time, a powerful combination for many careers is:

⭐ Project Management + Lean Six Sigma + Change Management

This gives you the skills to identify the right problems, deliver structured projects, and help people adopt and sustain the change.

How SSGI can help with Lean Six Sigma

If Lean Six Sigma is the right starting point for your goals, the next question is where to get certified.

If you decide Lean Six Sigma is the right starting point, SSGI offers:

Fully online, self paced Lean Six Sigma Yellow, Green Belt, Black Belt and Master Black Belt programs

Industry based examples across manufacturing, services, tech, government, and healthcare

No annual renewal fees

Training and certification developed by Dr. Barry Shore, a McGraw Hill award winning professor with more than 40 years of experience in operations management

Programs trusted by teams at organizations such as Disney, Walmart, Tesla, Maersk, Citizens Bank, Air Canada and many others

You can start with a single belt or follow a full progression from foundational through advanced continuous improvement leadership with a SSGI Career Track.

In short, PMP teaches you how to manage projects, while Lean Six Sigma teaches you how to improve the processes those projects change.

FAQs: Lean Six Sigma vs PMP

Is Lean Six Sigma harder than PMP?

Lean Six Sigma and PMP are challenging in different ways, so one is not universally harder than the other. Lean Six Sigma can be more technically demanding, especially at the Green Belt and Black Belt levels, because it requires data analysis, statistical thinking, and structured problem-solving. PMP is often considered more challenging from a breadth and experience perspective, as it requires documented project management experience and mastery of a broad project management framework. Which feels harder depends on whether you are more comfortable with data-driven analysis or managing complex projects and stakeholders.

Which certification pays more, Lean Six Sigma or PMP?

Both certifications are associated with strong salary increases, and which pays more depends on role and industry. PMP certification is often linked to higher salaries in formal project management, IT, construction, and consulting roles. Lean Six Sigma certification tends to drive higher pay in operations, quality, manufacturing, healthcare, and continuous improvement roles. In practice, professionals who hold both certifications often see the greatest long-term earning potential because they can both improve processes and lead large initiatives.

Do employers prefer PMP or Lean Six Sigma?

Employers do not universally prefer one certification over the other. PMP is often explicitly required for project manager and program manager roles, especially in organizations that run work primarily through projects. Lean Six Sigma is preferred in roles focused on operational excellence, quality, efficiency, and cost reduction. Many employers value Lean Six Sigma for its practical, results-oriented approach and PMP for its ability to manage complex initiatives. The preferred certification depends on the nature of the role rather than the prestige of the credential.

Can Lean Six Sigma replace PMP?

Lean Six Sigma does not replace PMP, and PMP does not replace Lean Six Sigma. They serve different purposes. Lean Six Sigma focuses on improving how work is done by fixing broken or inefficient processes, while PMP focuses on planning and delivering projects that implement change. In many organizations, Lean Six Sigma identifies what should be improved, and PMP provides the structure to execute that improvement at scale. For professionals who want broader impact and leadership opportunities, combining both certifications is often more effective than choosing only one.

Is Lean Six Sigma better than PMP?

Neither is universally better. PMP is better if your primary role is leading projects. Lean Six Sigma is better if your primary role is improving processes and operational performance. Many professionals eventually do both and use them together.

Six Sigma vs PMP: What’s the difference?

Six Sigma focuses on improving processes by eliminating defects, reducing variation, and solving operational problems using data-driven tools. PMP focuses on managing projects — including timelines, budgets, risks, and stakeholders — to deliver a defined scope successfully.

In simple terms:

Six Sigma improves processes. PMP manages projects.

Many professionals use Six Sigma to fix workflows and PMP to manage the projects that implement those improvements.

Can I do Lean Six Sigma and PMP at the same time?

It is possible, but most people get better results by focusing on one at a time so they can apply what they learn through real projects. A common sequence is Lean Six Sigma Green Belt first, then PMP once you are leading larger initiatives.

Should I get PMP or Lean Six Sigma first?

It depends on your role and your goals.

If your work involves fixing broken processes, improving efficiency, reducing errors, or leading operational change, then Lean Six Sigma is usually the better first step. It gives you practical tools for solving problems, improving workflows, and delivering measurable results quickly.

If you are already working in project management, coordinating cross-functional teams, managing timelines, budgets, and deliverables — or applying for roles where PMP is explicitly required — then PMP is typically the right place to start.

A simple rule of thumb:

Start with Lean Six Sigma if your job focuses on improving how work gets done.

Start with PMP if your job focuses on delivering structured projects on time and on budget.

Many professionals eventually earn both, using Lean Six Sigma to improve processes and PMP to manage the projects that implement those improvements.

Do employers recognize Lean Six Sigma as much as PMP?

PMP is often listed explicitly in project manager job descriptions, especially in IT, construction, and large transformation programs. Lean Six Sigma is widely recognized in operations, quality, manufacturing, healthcare, and service environments where process improvement is a priority. Both are widely respected and can be strong assets on your resume

Does Lean Six Sigma expire?

Most Lean Six Sigma certifications do not require periodic renewal, although this can vary by provider. PMP certification must be renewed every three years by earning 60 PDUs and paying a renewal fee.

What if I am still unsure which certification to start with?

Look at your current role and the jobs you want over the next 3 to 5 years:

If job descriptions mention process improvement, quality, Lean, Six Sigma, continuous improvement, or operational excellence, start with Lean Six Sigma.

If job descriptions mention project manager, program manager, implementation lead, PMO, and list PMP explicitly, prioritize PMP.

You can always add the other credential once you have built experience and are ready for the next step.