Lean Six Sigma Jobs are a Great Career Choice

Are you curious about getting Lean Six Sigma certified, but unsure about the types of jobs that are applicable to a Six Sigma certified professional? Don’t worry, you’re not alone. In this article we will discuss the various job roles, functions and industries that relate to Lean Six Sigma, as well as the respected salaries you can expect upon becoming six sigma certified.

First, Lean Six Sigma is a methodology that combines the principles of Lean and Six Sigma to improve processes and reduce waste in organizations. This methodology has gained popularity in recent years, and as a result, there is an increasing demand for Lean Six Sigma professionals in various industries.

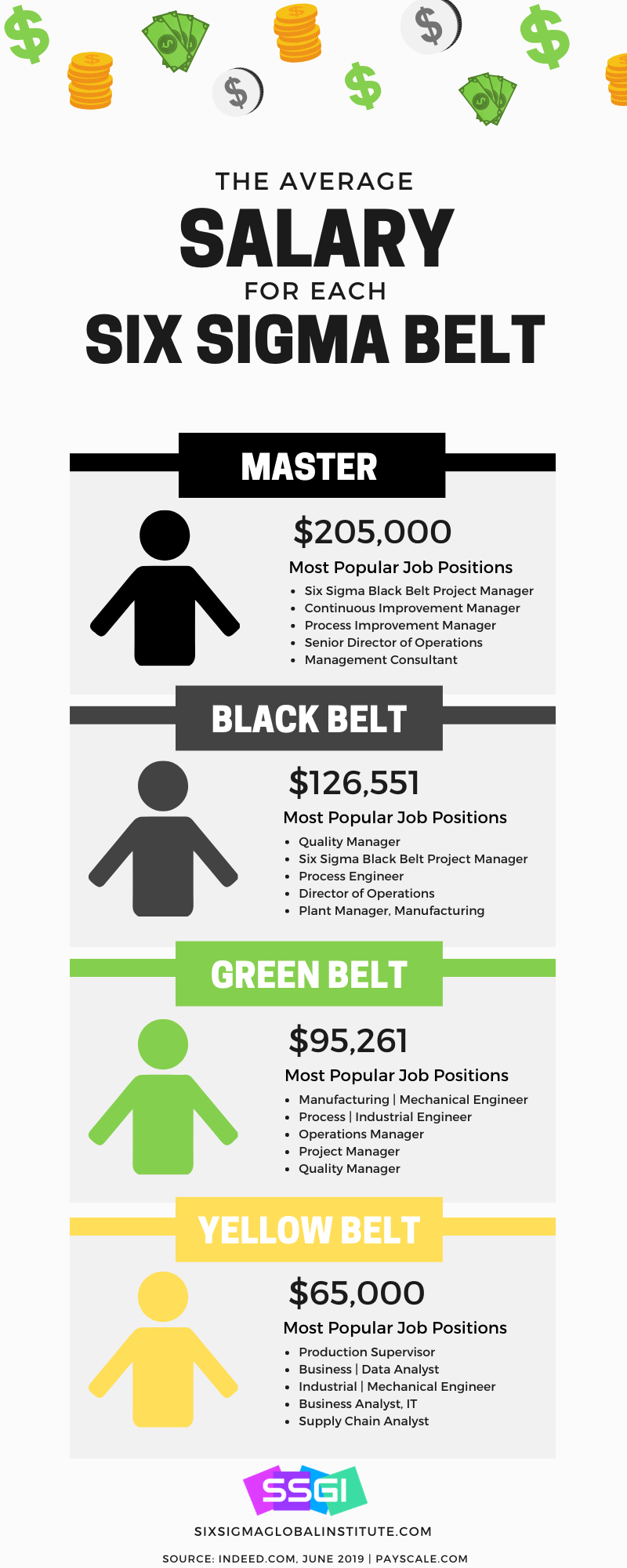

There are several job roles associated with Lean Six Sigma, including Black Belts, Green Belts, Yellow Belts, Master Black Belts, Process Owners, Data Analysts, Project Managers, and Trainers. These roles require a combination of technical and soft skills, such as problem-solving, communication, leadership, and project management.

Lean Six Sigma Black Belts

Black Belts are highly trained professionals who lead and manage Lean Six Sigma projects and provide training and mentorship to Green Belts. According to PayScale, the average salary for a Lean Six Sigma Black Belt in the United States is $96,000 per year, with a range of $67,000 to $134,000 per year. The salary for this role can vary depending on factors such as industry, company size, and location.

Lean Six Sigma Green Belts

Green Belts are trained professionals who lead and participate in Lean Six Sigma projects and provide support to Black Belts. According to PayScale, the average salary for a Lean Six Sigma Green Belt in the United States is $76,000 per year, with a range of $53,000 to $107,000 per year.

Master Black Belts

Master Black Belts are senior-level executives who provide support, resources, and leadership to Lean Six Sigma initiatives. According to PayScale, the average salary for a Lean Six Sigma Champion in the United States is $138,000 per year, with a range of $80,000 to $225,000 per year.

Process Owners

Process Owners are responsible for specific business processes and work with Lean Six Sigma teams to identify and eliminate waste and improve process efficiency. According to PayScale, the average salary for a Process Owner in the United States is $82,000 per year, with a range of $50,000 to $128,000 per year.

Data Analysts

Data Analysts use statistical analysis and data interpretation to identify areas for improvement in processes and make informed decisions. According to PayScale, the average salary for a Data Analyst in the United States is $62,000 per year, with a range of $43,000 to $87,000 per year.

Project Managers

Project Managers are responsible for managing Lean Six Sigma projects, including defining project goals, developing project plans, and tracking progress. According to PayScale, the average salary for a Project Manager in the United States is $78,000 per year, with a range of $51,000 to $120,000 per year.

Trainers

Trainers are responsible for providing training and education on Lean Six Sigma methodologies and tools. According to PayScale, the average salary for a Trainer in the United States is $59,000 per year, with a range of $36,000 to $92,000 per year.

The demand for Lean Six Sigma professionals is increasing, and the salaries for these roles are competitive. The salary for a Lean Six Sigma professional can vary depending on the job role, industry, company size, and location. However, with the right skills and experience, Lean Six Sigma professionals can have rewarding careers in various industries.